Our biogas projects

Rückert NatUrgas process

Individual solutions

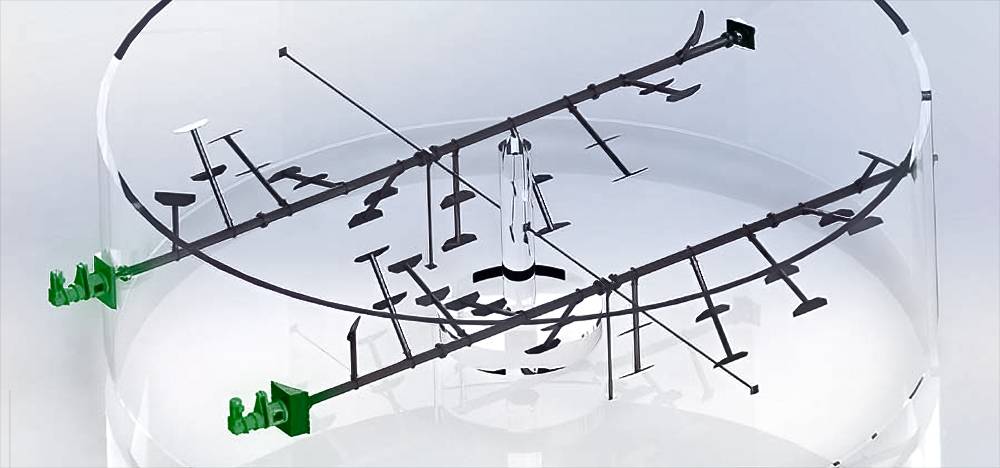

Why comes more gas with the right agitator?

Two reel agitators running against each other (concrete mixer principle), longitudinal agitators with horizontal axis.

≥ 76 % (!) sweep of the fermenter contents = good mixing of the fermenter contents, substrate independence.

Two paddle agitators correspond to a very slow circular movement.

≤ 7 % (!) overcoating of the substrate, only punctual mixing of the fermenter contents, substrate is only mixed in places, larger fermenter volumes required.

Here you can download our fermenter concept and substrate comparison

Our Projects

No results found.