Our Projects

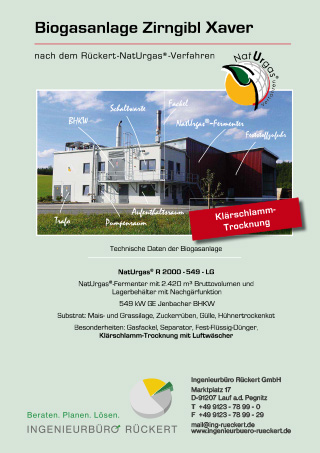

Biogas plant Zirngibl with sewage sludge drying

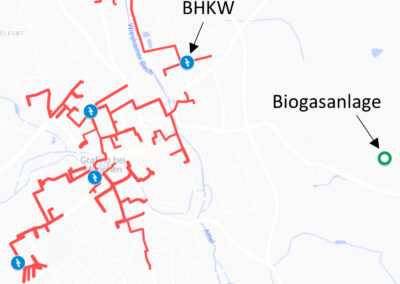

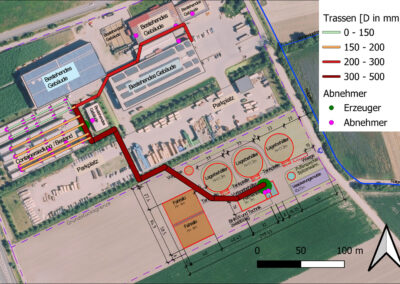

Sewage sludge drying as a heat utilisation concept

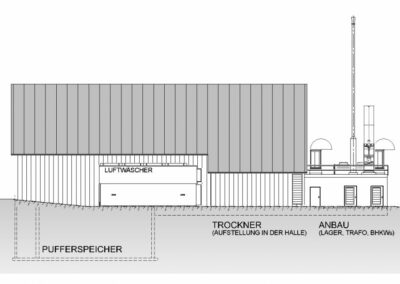

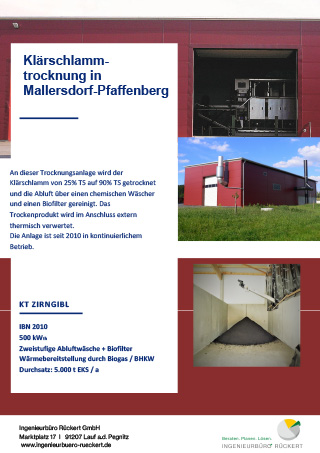

In order to use the surplus heat from the combustion of biogas, a sewage sludge drying plant was built next to the biogas plant. It accepts sewage sludge from the region, which has been dewatered to high solids content using centrifuges and chamber filter presses. Air is used for drying, which is heated before the dryer. The exhaust air is cleaned in several stages. After a retention time of about two hours, the dried sewage sludge is conveyed to the designated storage area by means of a discharge screw. The dried sewage sludge is then utilised for energy.

At this plant, sewage sludge is dried independently and then thermally utilised. The plant supplies itself with electricity via a steam turbine.

The exhaust air from the dryer is cleaned via a multi-stage exhaust air scrubber. The waste gas from the incineration is used thermally and cleaned via the dry flue gas cleaning system.

The decentralised nature of the plant avoids long transport routes and thus saves CO2. In addition, the phosphorus can be recovered from the ash and returned to the natural cycle.

More information at:

Our activities:General planning, project coordination

Here you can find our profiles as PDFs