Our projects

Feasibility study for conversion to renewable energy supply Vegetable farm

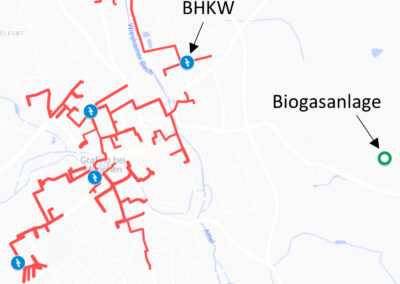

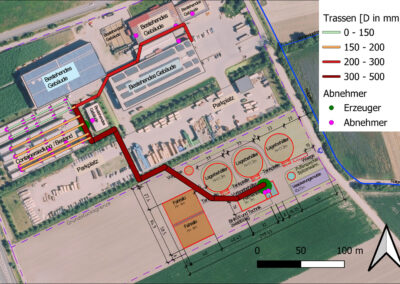

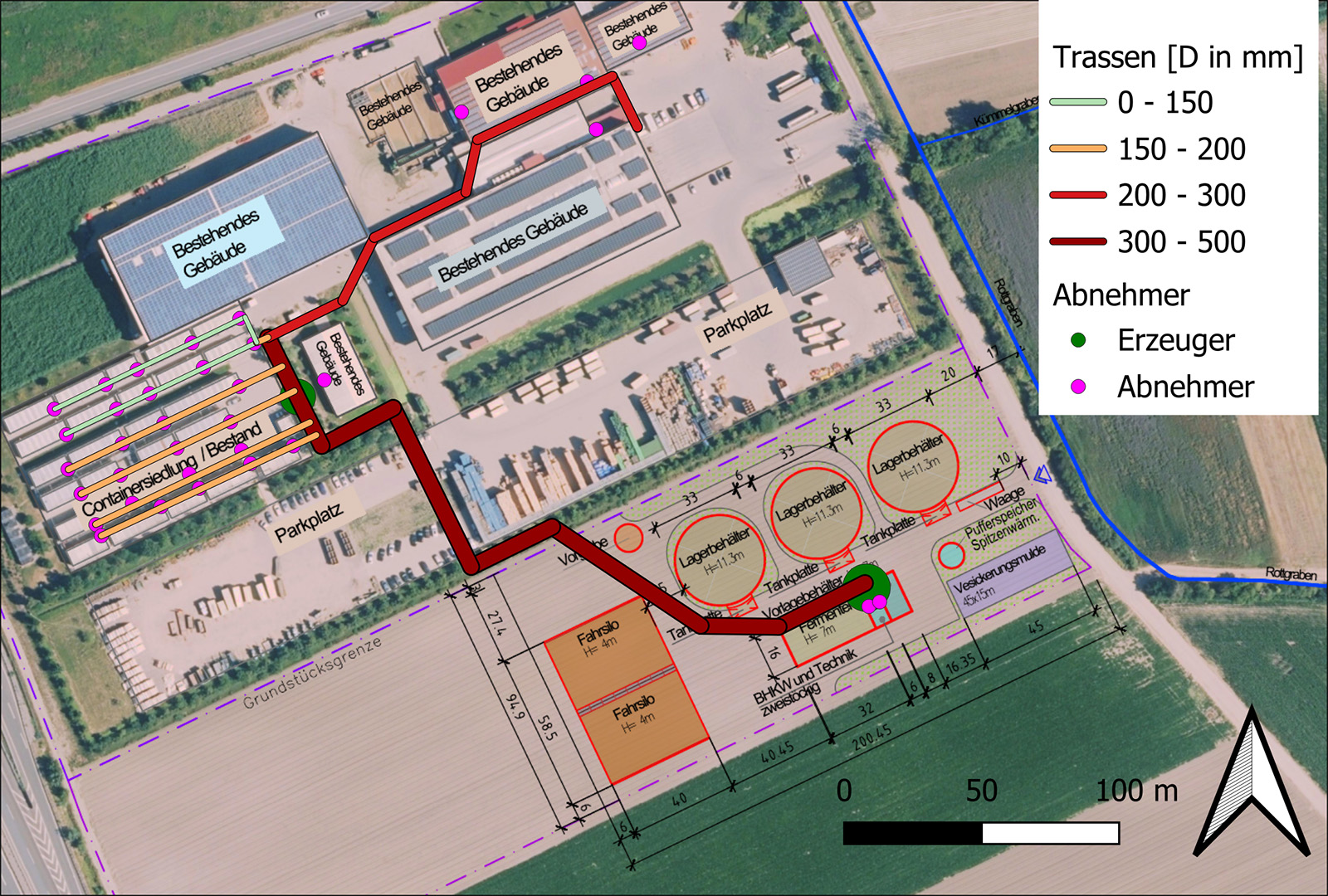

At the site of a vegetable farm, a feasibility study, including a profitability analysis, was carried out into the conversion to renewable energy supply by means of a local heating network. The aim is to utilise vegetable waste from the farm and other renewable raw materials in a biogas plant and to supply 100% of the electricity, heating and cooling via biogas CHP units.

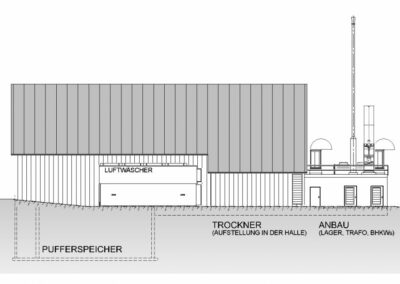

After analysing the existing supply to the production halls, the office building, the workshop and the container housing estate with up to 800 residents, the potential for generating energy from the company’s own vegetable waste was determined and the need for additional cultivation of renewable raw materials was quantified. When analysing various scenarios for supplying the business, the conversion of the container housing estate (400 units) from electricity and gas heating appliances and instantaneous water heaters to heat from the CHP units (2.75 MW combustion heat output) and the construction of a biogas plant with a CHP unit were identified as the most cost-effective measures in the long term. Covering the entire electricity requirement, especially for the cold store and pumps, from the company’s own cultivation also promises the greatest possible reduction in CO2 emissions. A 9.0 MWh heat storage tank and the distribution of CHP output across three CHP units are planned to cover peak heating requirements. The heat will be transported from the CHP units to the heat storage tank and to the consumption points on the site via a heating network.

Our activities:

Inventory analysis, potential analysis, scenario development, proposals for measures, rough dimensioning, preparation of authorisation